Recycling artificial turf is essential for sustainability. Transitioning from multi-materials to mono-materials, like ONE-DNA™ turf, enables high-quality recycling and supports a circular economy.

What is Recycling?

Recycling converts waste materials into new products, conserving natural resources and reducing landfill waste. Artificial turf is often made of various materials like PE and PP, which have different melting points and chemical properties, making recycling complex.

Challenges in Recycling Artificial Turf

- Complex Separation: Separating different materials is technically and energy-intensive, making the recycling process less efficient and more expensive.

- Different Melting Points: Materials like PE and PP have different melting points, making it impossible to recycle them together without quality loss.

- Quality Loss: Recycled products made from mixed materials are often of lower quality and less versatile due to inconsistent melting and contamination.

Practical Examples

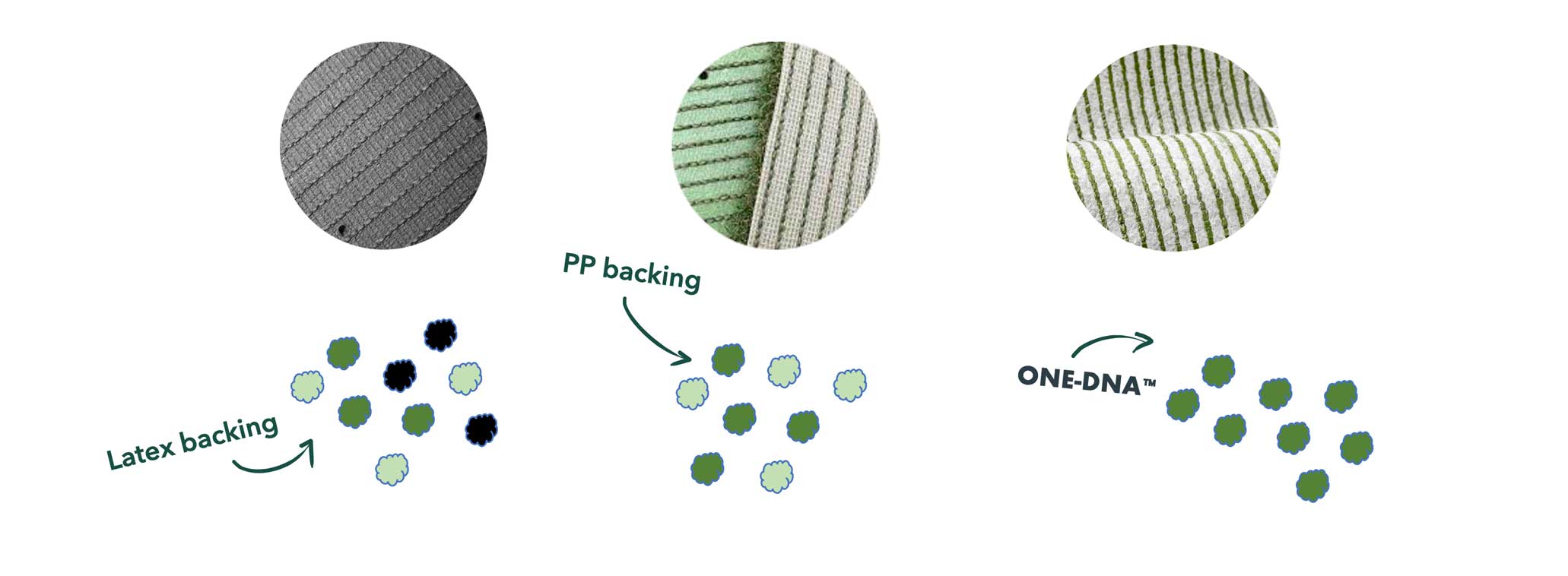

- Mix of PE and PP: Although better than a multi-stream approach, a mix of PE and PP remains problematic due to different melting points, requiring complex separation processes.

- Mix of PE, PP, and Latex: Some artificial turf products contain a mix of PE, PP, and latex, further complicating the recycling process. Latex has entirely different chemical properties and melting points, increasing the costs and energy consumption for recycling.

The Solution: Mono-Material Artificial Turf

To achieve high-quality recycling in the future, products must eliminate or significantly simplify the separation process. This can be achieved by using mono-materials, where the entire product is made from a single polymer, such as ONE-DNA™ artificial turf.

Advantages of Mono-Material Artificial Turf

- Simplified Recycling: With only one type of material, the separation process is unnecessary, increasing efficiency and reducing costs.

- Higher Quality Recycled Material: Mono-materials ensure that the recycled product is of higher quality, improving usability and durability.

- Sustainability and CO2 Reduction: The production process for mono-materials is often less energy-intensive, resulting in lower CO2 emissions.

ONE-DNA™ Artificial Turf: A Circular Product

ONE-DNA™ artificial turf, produced by LimeGreen, is known for being a circular product due to its use of a single base material: polyethylene (PE). This design facilitates recycling and reuse and offers significant advantages over traditional multi-material artificial turf products.

Recycling Efficiency: Because ONE-DNA™ circular artificial turf is made entirely of PE, it can be easily recycled without separating different polymers.

Value Retention: Unlike mixed polymers, which are often downcycled into less valuable streams, a 100% PE product can be recycled into high-quality applications such as new turf or other PE products.

Environmental Product Declaration (EPD)

ONE-DNA™ circular artificial turf is supported by an Environmental Product Declaration (EPD), a detailed and standardized document that assesses the product’s environmental impact throughout its entire lifecycle, from raw material extraction to end-of-life. The EPD provides transparency on sustainability performance and highlights the product’s low ecological footprint. This transparency helps businesses and consumers make informed decisions based on reliable environmental data, underscoring ONE-DNA™’s commitment to a sustainable future.

Integration of the Take Back Program

Integration of the Take Back Program

Take Back Program and Registration App: The Take Back Program ensures that used artificial turf doesn’t end up in landfills but is repurposed into new PE products. This program is supported by the Take Back Registration App, which allows our changemakers to register the ONE-DNA™ turf upon installation with the customer. The registration includes essential details such as product type, roll number, and installation location. This data is securely stored in our database, and customers automatically receive the Take-Back Certificate and Warranty Certificate via email.

Conclusion

The transition to mono-material artificial turf, supported by the Take Back Program, is essential for a sustainable future. By developing products that minimize the need for separation processes, the quality of recycled material is enhanced, and environmental impact is reduced. It is a key step towards a circular economy and supports sustainability goals like those outlined in the European Green Deal and the Sustainable Development Goals (SDGs).

More Information For more information on artificial turf recycling and the benefits of mono-materials, visit these resources:

By consciously choosing sustainable artificial turf and recyclable solutions, we can contribute to a better environment and a circular economy.