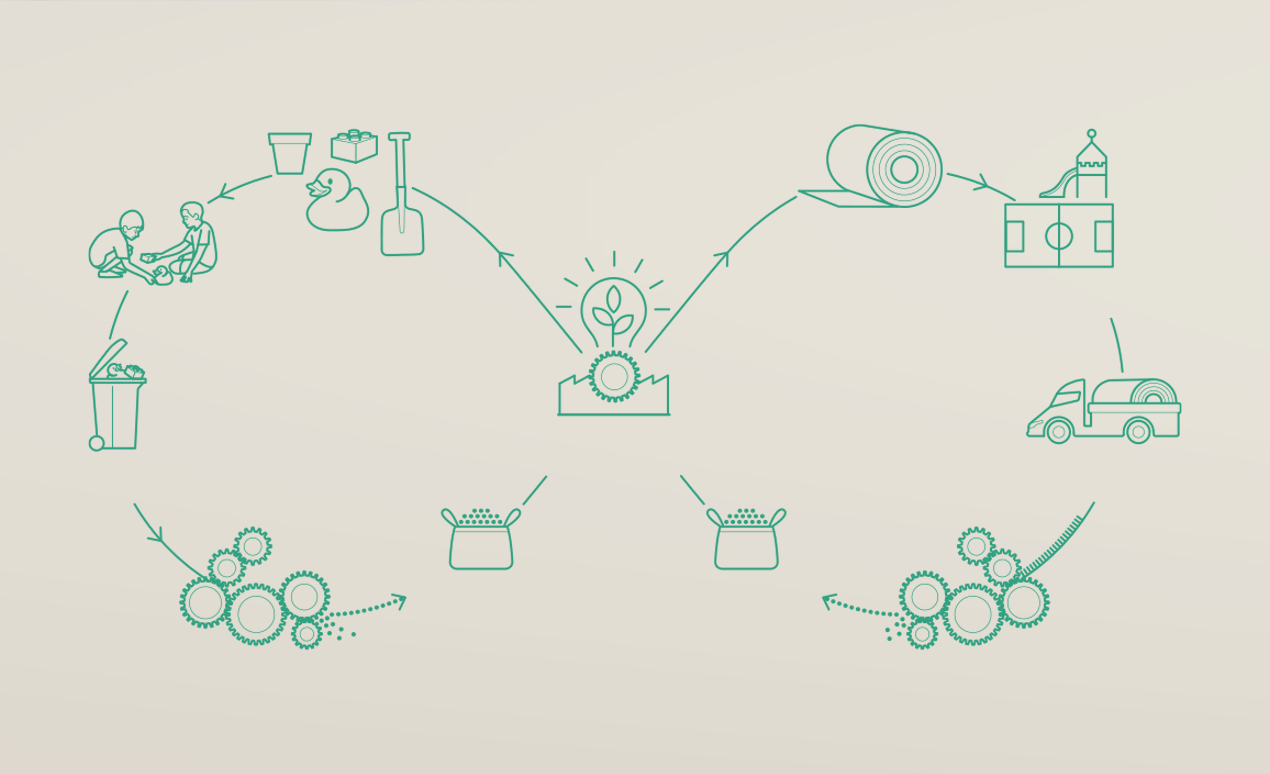

Recycling artificial grass is becoming an increasingly important topic in the quest for sustainability. To minimize the environmental impact of artificial grass, it is essential to shift from a multi-stream (various materials) to a mono-stream (single material) approach. This shift enables high-quality recycling and supports a circular economy.

What is Recycling?

Recycling is the process of converting waste materials into new products. The goal is to conserve natural resources and reduce the amount of waste sent to landfills. Recycling artificial grass is complex and energy-intensive due to its composition of various materials such as polyethylene (PE), polypropylene (PP) for the fibers, and a coating of PP, latex, or PU.

Challenges in Recycling Artificial Grass

Recycling artificial grass is complicated by the different materials it consists of. These materials have different melting points and chemical properties, which means the recycled material often can only be used for lower-quality products, a process known as downcycling.

- Complex Separation Process: Separating different materials requires advanced technologies and is energy-intensive, making the recycling process less efficient and more costly.

- Different Melting Points: Materials like PE and PP have different melting points, making it impossible to recycle them together without losing quality. For example, PE melts at about 120°C, while PP melts around 165°C.

- Quality Loss: Recycled products from mixed materials are often of lower quality and less versatile for new applications due to inconsistent melting and the presence of contaminants.

The Solution: Mono-Material Artificial Grass

To enable high-quality recycling of artificial grass in the future, products must be introduced that make the separation process unnecessary or significantly simplified. This can be achieved by using mono-materials, where the entire product is made from a single type of polymer, such as ONE-DNA™️ artificial grass.

Benefits of Mono-Material Artificial Grass

- Simplified Recycling: With one type of material, the separation process is unnecessary, increasing efficiency and reducing costs.

- Higher Quality Recycled Material: Mono-material ensures recycled material is of higher quality, improving the usability and durability of the recycled product.

- Sustainability and CO2 Reduction: The production process for mono-materials is often less energy-intensive, leading to lower CO2 emissions.

ONE-DNA™ Artificial Grass: A Circular Product

ONE-DNA™ artificial grass, produced by LimeGreen, is known as a circular product thanks to its use of a single base material: polyethylene (PE). This design facilitates recycling and reuse and offers significant advantages over traditional artificial grass products made from multiple materials.

Mono-Material Artificial Grass

- Recycling Efficiency: Since ONE-DNA™ circular artificial grass is made entirely of PE, it can be easily recycled without the need to separate different polymers.

- Value Retention: Unlike mixed polymers, which are often downcycled to lower-value streams, a 100% PE product can be recycled into high-quality applications such as new artificial grass or other PE products.

Multi-Material Artificial Grass

- Complex Separation: Traditional artificial grass uses different polymers for the fibers and backing, complicating separation and recycling at the end of its life. Mechanical recycling of mixed polymers often results in inferior materials.

- Lower Value: Multi-material artificial grass often ends up as low-value recyclate, suitable for less critical applications, contributing to waste and loss of valuable materials.

Differences in Melting Points and Reuse

Melting Points of Polymers: Different polymers have varying melting points, causing complications during the recycling process. When materials with different melting points are melted together, they cannot mix properly, resulting in a heterogeneous material with reduced mechanical properties.

Advantages of PE: PE has a consistent melting point, resulting in a homogeneous material that is easier and more efficient to recycle without loss of quality. This uniform melting point avoids the problems that arise when processing multi-material artificial grass, where varying melting temperatures lead to poor material bonding and lower product quality.

Environmental Product Declaration (EPD)

LimeGreen’s ONE-DNA™ circular artificial grass is supported by an Environmental Product Declaration (EPD), which assesses the product’s environmental impact throughout its life cycle. This declaration highlights the sustainability performance and low ecological footprint of the product.

- Lower Environmental Impact: By using a single material and avoiding harmful substances, ONE-DNA™ circular artificial grass minimizes emissions and waste during production, use, and end-of-life processing.

- Long-Lasting Durability: Tests show that the material degrades minimally after years of exposure to UV radiation, temperature fluctuations, and moisture, extending its lifespan and reducing the need for replacement.

In Practice

- Mix of Polyethylene (PE) and Polypropylene (PP): A mix of PE and PP, though better than a multi-stream with more material variety, remains problematic. The different melting points and chemical properties of these materials complicate the recycling of artificial grass. PE melts at about 120°C, while PP melts at around 165°C. This difference in melting points requires complex and costly separation processes.

- Mix of Polyethylene (PE), Polypropylene (PP), and Latex: Some artificial grass products contain a mix of PE, PP, and latex, further complicating the recycling process. Latex, a natural rubber, adds another layer of complexity due to its entirely different chemical properties and melting point. These types of multi-materials require advanced separation technologies, increasing the cost and energy consumption of recycling artificial grass. Additionally, the recycled material often results in lower-quality products due to the diverse melting and processing properties.

- ONE-DNA™ Artificial Grass: This is an example of mono-material artificial grass, where the entire product is made from polyethylene (PE). This simplifies and makes the recycling process efficient.

Conclusion

The transition to mono-material artificial grass is essential for a sustainable future. By developing products that minimize the need for separation processes, the quality of recycled material is enhanced, and environmental impact is reduced. It is an important step toward a circular economy and supports sustainability goals such as those of the European Green Deal and the Sustainable Development Goals (SDGs).

Learn More

For more information on recycling artificial grass and the benefits of mono-materials, visit these sources:

By consciously choosing sustainable artificial grass and recyclable solutions, we can contribute to a better environment and a circular economy.