Recycling is essential to promote a circular economy. An important aspect of recycling is the creation of monostreams, the separation of raw materials into pure streams. But why not design products that are already mono streams? This would eliminate the need to separate materials. In this blog post, we explore the benefits of monostreams and how we apply these principles to ONE-DNA™ artificial grass to promote sustainability.

Why Monostreams?

- Improved recyclability Monostreams make recycling much more efficient. When materials are separated into a pure, single stream, they can be better recycled without loss of quality. This reduces the complexity of the separation process and improves the quality of the recycled materials. Examples from the packaging industry show how single streams improve the recyclability of products.

- Monostream recycled materials retain their original quality and purity. This means that recycled materials can be reused in high-value applications, preventing downcycling and extending the life of raw materials.

- Cost savings Separating and recycling mono streams can be cost saving. Pure material streams require less energy and less sophisticated technology to recycle, resulting in lower operating costs for recycling facilities.

- Sustainability and environmental benefits Monostreams help reduce the environmental impact of recycling processes. By ensuring material purity, the need for virgin raw materials is reduced and less energy is consumed during production and recycling.

ONE-DNA™ Artificial Turf: One step forward

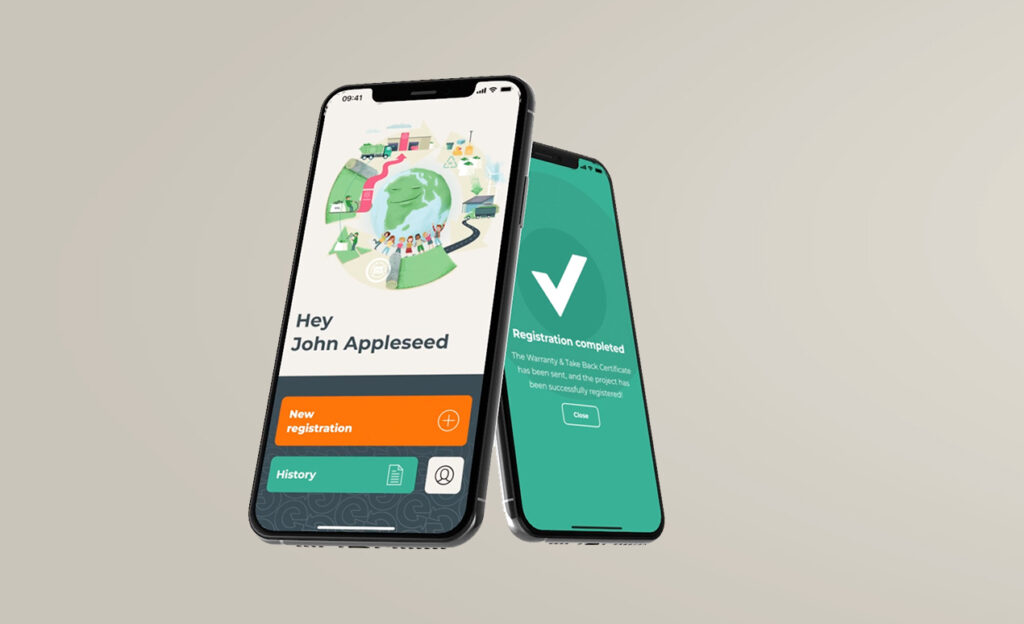

Our ONE-DNA™ artificial grass concept is a perfect example of how monostreams can be applied in practice. Traditional artificial turf is made up of different types of polymer, which makes it difficult to recycle. In contrast, our ONE-DNA™ artificial grass is made from a single type of polymer, making the product a monostream.

Advantages of ONE-DNA™ Artificial Turf:

- Easier to recycle: By using one type of polymer, ONE-DNA™ turf can be recycled more easily and efficiently without the need for complex separation techniques.

- High quality: The recycled materials retain their quality and purity and can be reused in high quality applications, contributing to a sustainable materials cycle.

- Reduced environmental impact: The production and recycling of ONE-DNA™ synthetic turf requires less energy, resulting in lower CO2 emissions and a smaller carbon footprint.

Industry examples

Packaging Industry

In the packaging industry, monostreams/mono-materials are already a major trend. Several companies demonstrate how mono-materials improve the recyclability of packaging and contribute to sustainability.

- Mono-material packaging: A recycler’s wish

- Mono-material: A Ray of Hope – Interpack

- Berlin Packaging: Flexibles

- Recycling Today: Setting a New Standard in Mono-Material Packaging

Adidas & Nike

The importance of mono streams is also recognised in the sportswear industry.

- Adidas Futurecraft Loop – LinkedIn

- Adidas Sustainability: Circularity

- Nike: Mono-material products optimize the recycling process

- Nike: Designing with the end in mind

Polestar

In the automotive industry, Polestar is using mono-materials to improve the recyclability of its products and contribute to a more sustainable future.

Other examples

Other companies and initiatives also show how mono-materials can be used for sustainability:

Conclusion

Monostreams offer numerous benefits to the recycling industry and are essential to achieving a circular economy. ONE-DNA™ artificial grass uses these principles to create high quality, sustainable products that are easy to recycle. By choosing Monostreams, we can work together towards a future where waste is a thing of the past and materials are continuously reused.