Monomaterial solutions in the world of packaging are gaining ground as the key to a more sustainable future. It is predicted that mono-material packaging will dominate the industry by 2030. In this article, we explore the differences between mono-material and multi-material solutions and explain why we believe that ONE-DNA™️, monomaterial artificial grass, is the future!

WHAT’S THE DIFFERENCE?

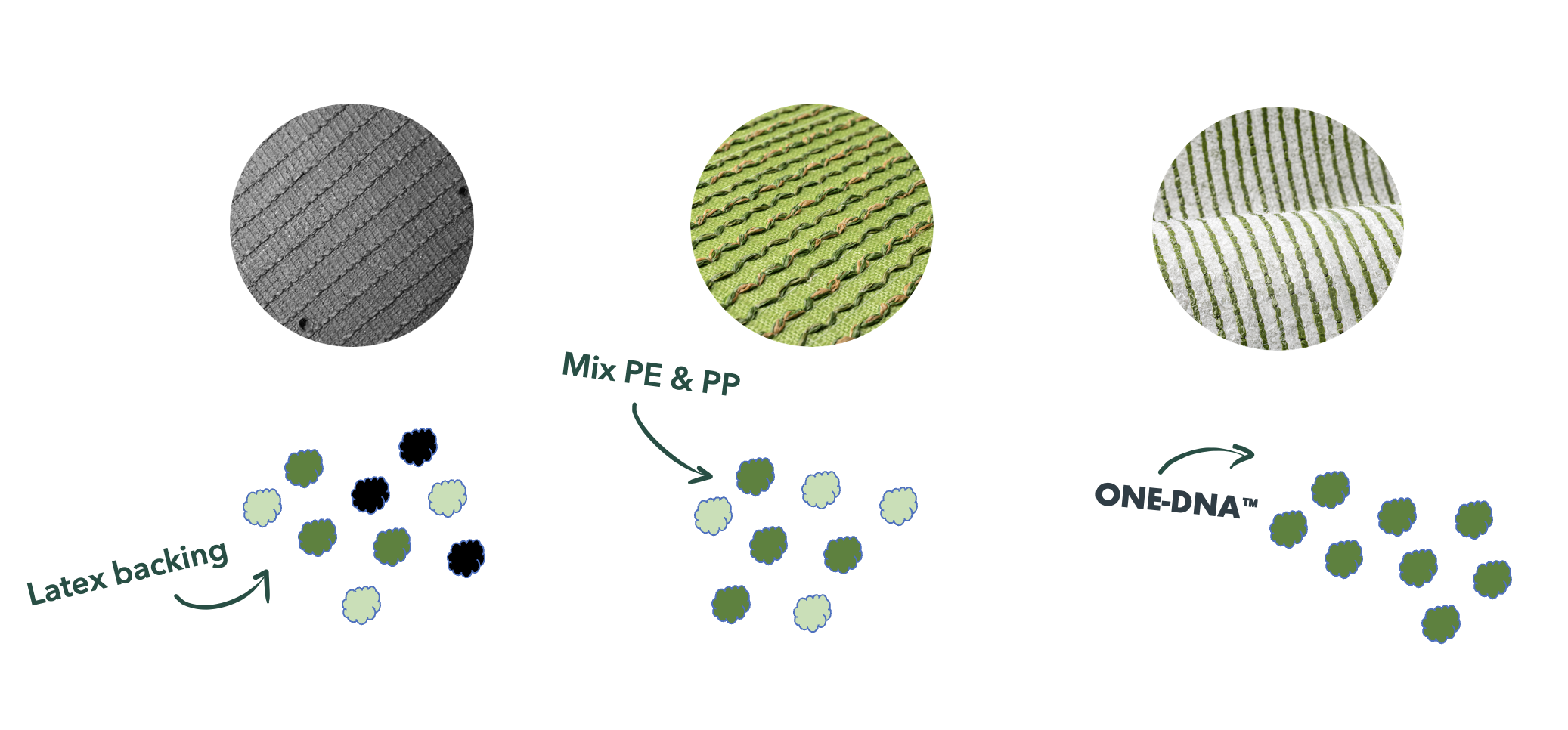

- Mono-material structures: Mono-material structures consist of only one type of material. This means that the entire product is made from a single homogeneous material, i.e. one type of polymer. An example of this is mono-material artificial turf, such as ONE-DNA™. The advantage of mono-material structures is that the material can be easily recycled and reused.

- Multi-material structures: Multi-material structures consist of different materials that are combined to achieve the desired properties. For artificial turf, think of a mixture of PP & PE, and often a backing material, and a coating of PP, latex or PU. This creates recycling challenges.

The Importance of MONOMATERIAL

The main differences between mono-material and multi-material structures in the artificial grass industry are:

- Monomaterial: Mono-material, such as ONE-DNA™, is designed with sustainability in mind. Using only one type of polymer makes recycling and reuse more efficient. This reduces CO2 emissions during production and minimises the use of raw materials, contributing to sustainability goals. Mono-material structures support circularity as the material can be reused.

- Multi-material: Multi-material artificial grass is made up of different raw materials, such as PE & PP, which makes recycling difficult. Recycling different materials results in a loss of value and a larger carbon footprint. Multi-material artificial grass has limited potential for reuse and can usually only be reused in thick-walled products, such as picnic tables, due to the challenges of processing different materials.

ADVANTAGES OF MONO-MATERIAL

Mono-material products, such as ONE-DNA™️ artificial grass, offer several advantages in terms of both sustainability and efficiency:

- Simplified recycling: Mono-material products are easier to recycle than multi-material products. This increases the likelihood that they will actually be recycled.

- Waste reduction: Using a single material reduces the amount of waste, both during production and at the end of the product’s life cycle.

- Energy savings: The recycling process for mono-material products is generally more energy efficient as less energy is required to process the material.

- Sustainability: Mono-material products support a circular economy through their reusability and recyclability, contributing to a more sustainable future.

- Cost savings: Mono-material products can be less expensive to produce and recycle than multi-material products due to the simplicity of the production process and reduced waste.

- Increased consumer awareness: Mono-material products respond to growing consumer demand for more sustainable and environmentally friendly products.

GREENER FUTURE

The focus within the packaging sector is shifting towards the use of mono-materials, a move that underlines the increasing emphasis on sustainability and the circular economy in various industries. This approach limits waste production, reduces CO2 emissions and contributes to a greener future. Here are some links to related articles:

- https://knaufappliances.com/mono-material-packaging

- https://www.smithers.com/resources/2020/aug/easy-to-recycle-mono-material-film-packs-to-grow

- https://packagingeurope.com/comment/a-closer-look-at-the-potential-of-the-mono-material-packaging-market/8908.article

- https://www.ptonline.com/blog/post/monomaterial-trend-in-packaging-and-beyond-will-only-thrive